價(jià)格:38450元瀏覽:92次聯(lián)系:劉元元 / 15132636097 / 企業(yè):北京北廣精儀儀器設(shè)備有限公司留言店鋪收藏

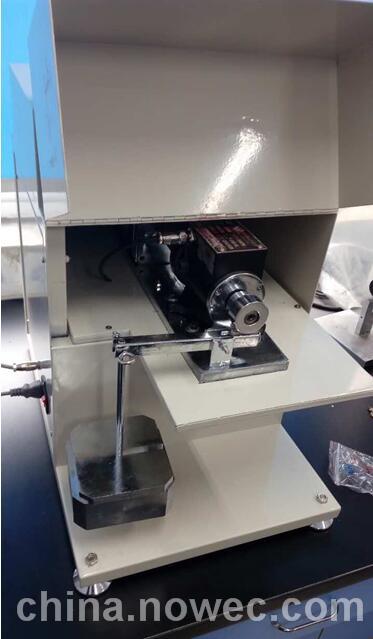

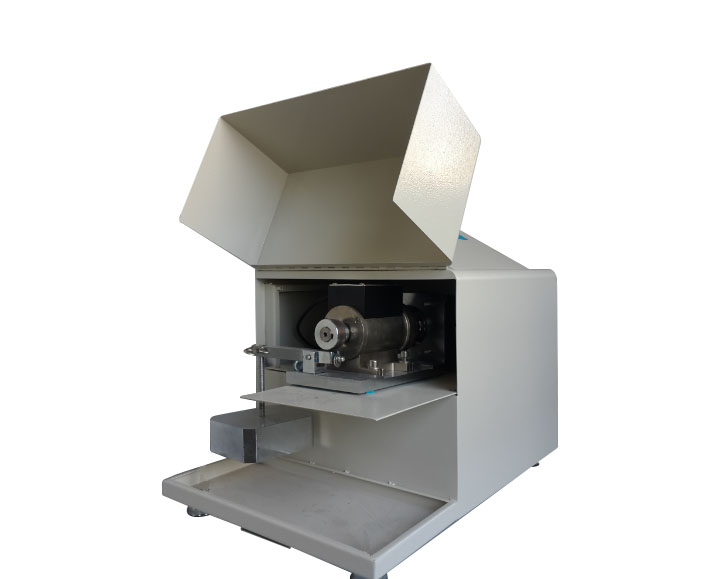

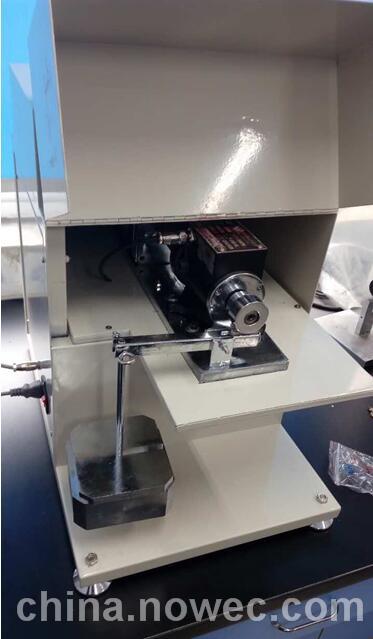

塑料滑動(dòng)摩擦磨損試驗(yàn)機(jī) 功能:

本廠生產(chǎn)的計(jì)算機(jī)控制塑料滑動(dòng)摩擦試驗(yàn)機(jī)是在現(xiàn)有電子塑料滑動(dòng)摩擦試驗(yàn)機(jī)的基礎(chǔ)上又增加了很多試驗(yàn)功能,可以同時(shí)顯示扭矩-時(shí)間曲線,隨意設(shè)定試驗(yàn)次數(shù),顯示當(dāng)前試驗(yàn)次數(shù),設(shè)定時(shí)間及當(dāng)前試驗(yàn)時(shí)間等多種功能,本機(jī)還配有彩色打印機(jī),可以打印出帶有曲線,表格數(shù)據(jù),試驗(yàn)單位名頭的精美的試驗(yàn)報(bào)告單。

塑料滑動(dòng)摩擦磨損試驗(yàn)機(jī) 特點(diǎn):

1、系統(tǒng)運(yùn)行穩(wěn)定,可靠性高。

2、結(jié)構(gòu)緊湊,使用方便,簡(jiǎn)單。

3、采用高精度電機(jī)、驅(qū)動(dòng)機(jī)、傳感器,精度高。

4、具有試驗(yàn)人員分級(jí)管理功能。

5、實(shí)時(shí)顯示摩擦系數(shù)-時(shí)間,扭矩-時(shí)間曲線。

6、試驗(yàn)報(bào)告可打印試驗(yàn)參數(shù),試驗(yàn)數(shù)據(jù),曲線,備注等信息,簡(jiǎn)單,方便,可編輯。

7、試樣尺寸: 30mm?7mm?6mm

8、轉(zhuǎn)動(dòng)速度: 0-500轉(zhuǎn)/分 (可調(diào))

9、負(fù) 荷: 196N ? 0.1%(可增至392N)

10、摩擦環(huán)尺寸:¢40?10mm ,倒角0.5?45?,外圓表面與內(nèi)圓同心度偏差小于0.01

11、摩擦環(huán)材質(zhì):45號(hào)鋼,淬火,熱處理HRC40-45,外圓表面光潔度▼8

12、摩擦力矩: 0--4N?m

13、砝碼重量:4KG砝碼一件,1KG砝碼4件,可實(shí)現(xiàn)重量疊加功能。

技術(shù)參數(shù):

1、速度精度:1%

2、負(fù)荷精度:0.5%

3、摩擦力矩精度:1%

4、計(jì)數(shù)器精度:1S

5、傳感器測(cè)量精度:1% FS

符合標(biāo)準(zhǔn):

GB/T 3960-1983 塑料滑動(dòng)摩擦磨損試驗(yàn)方法 GB/T 9141.8-1999 柔性石墨板材滑動(dòng)摩擦系數(shù)測(cè)試方法

主要配置及附件:(計(jì)算機(jī)控制)

1、試驗(yàn)主機(jī)一臺(tái)

2、高精度扭矩傳感器一只

3、計(jì)算機(jī)數(shù)據(jù)采集卡一塊

4、計(jì)算機(jī)一臺(tái)(品牌)

5、彩色激光噴墨打印機(jī)一臺(tái)

6、計(jì)算機(jī)控制軟件一套

7、4Kg 砝碼兩件(備用一套)

8、標(biāo)準(zhǔn)磨擦環(huán)四件(備用兩件)

9、產(chǎn)品使用說明書一份

10、產(chǎn)品合格證

11、產(chǎn)品裝箱單一份

12、整機(jī)重量:約87 公斤

硬件安裝及連線

1、將電源線插入設(shè)備后邊的電源插口。

2、將控制和采集線一端接到設(shè)備控制端口,另一端接到計(jì)算機(jī)上。

3、正確連接電腦接線

試樣要求

試樣表面平整,無氣泡、裂紋、分層、明顯雜質(zhì)和加工損傷等缺陷。每組試樣不少于3個(gè)。

試驗(yàn)條件

試驗(yàn)中上轉(zhuǎn)軸保持靜止,下轉(zhuǎn)軸以200轉(zhuǎn)/分轉(zhuǎn)動(dòng),摩擦副做滑動(dòng)摩擦,對(duì)磨2小時(shí),負(fù)荷20公斤,根據(jù)材料,允許選擇其它負(fù)荷.試驗(yàn)環(huán)境溫度為23?5攝氏度.

試驗(yàn)報(bào)告

試驗(yàn)報(bào)告應(yīng)包括下列內(nèi)容:

A.塑料名稱、規(guī)格、牌號(hào)、生產(chǎn)廠;

B.試樣的制備方法,摩擦表面狀況,測(cè)定的試樣個(gè)數(shù);

C.環(huán)境溫度、溫度及狀態(tài)調(diào)節(jié)條件;

D.圓環(huán)材質(zhì)、硬度、光潔度和外徑尺寸;

E.試驗(yàn)負(fù)荷;

F.試驗(yàn)結(jié)果:磨痕寬度或體積磨損及摩擦系數(shù)的測(cè)定結(jié)果;

G.試驗(yàn)日期、人員。

試驗(yàn)步驟

1、圓環(huán)應(yīng)清除油污,貯存于干燥缸內(nèi)以防生銹。

2、試樣經(jīng)狀態(tài)調(diào)節(jié)后用感量為0.1毫克的分析天平稱取其質(zhì)量(M1)。

3、把試樣裝進(jìn)夾具,摩擦面用角尺校正并使它與圓環(huán)的交線外于試樣正中。裝好摩擦力矩記錄紙,開機(jī)校好零點(diǎn)。

4、再次用乙醇、丙酮等不與塑料起作用的溶劑仔細(xì)清除試樣和圓環(huán)上的油污,此后不準(zhǔn)再用手接觸試樣和圓環(huán)的表面。

5、平穩(wěn)地加荷至選定的負(fù)荷值。

6、對(duì)磨2小時(shí)后停機(jī)卸負(fù)荷,取下試樣和圓環(huán),清理試樣表面后,用精度不低于0.02毫米的量具測(cè)量磨痕寬度,或在試驗(yàn)環(huán)境下存放1小時(shí)后稱取試樣質(zhì)量(m2)。

7、讀取摩擦力矩值。

狀態(tài)調(diào)節(jié)

狀態(tài)調(diào)節(jié)按GB2918-82《塑料試樣狀態(tài)調(diào)節(jié)和試驗(yàn)的標(biāo)準(zhǔn)環(huán)境》進(jìn)行,溫度為23?5攝氏度,溫度為50?10%。

Function:

The computer-controlled plastic sliding friction testing machine produced by our factory has added many testing functions on the basis of the existing electronic plastic sliding friction testing machine. It can simultaneously display the torque time curve, freely set the number of tests, display the current number of tests, set the time and the current test time, and other functions. The machine is also equipped with a color printer, which can print exquisite test reports with curves, table data, and test unit names.

characteristic:

1. The system runs stably and has high reliability.

2. Compact structure, easy to use, and simple.

3. Adopting high-precision motors, drivers, and sensors, with high precision.

4. It has the function of grading and managing experimental personnel.

5. Real time display of friction coefficient time and torque time curves.

6. The test report can print test parameters, test data, curves, notes, and other information, which is simple, convenient, and editable.

7. Sample size: 30mm?7mm?6mm

8. Rotation speed: 0-500 revolutions per minute (adjustable)

9. Load: 196N ? 0.1% (can be increased to 392N)

10. Friction ring size:¢40 ? 10mm, chamfer 0.5 ? 45 ?, concentricity deviation between outer and inner surfaces less than 0.01

11. Friction ring material: 45 steel, quenched, heat treated HRC40-45, outer surface smoothness ▼ 8

12. Friction torque: 0--4N?m

13. Weight of weights: One 4KG weight and four 1KG weights, which can achieve weight stacking function.

Technical parameters:

1. Speed accuracy: 1%

2. Load accuracy: 0.5%

3. Friction torque accuracy: 1%

4. Counter accuracy: 1S

5. Sensor measurement accuracy: 1% FS

Compliant with standards:

GB/T 3960-1983 Plastic Sliding Friction and Wear Test Method GB/T 9141.8-1999 Flexible Graphite Sheet Sliding Friction Coefficient Test Method

Main configuration and accessories: (computer-controlled)

1. One experimental host

2. One high-precision torque sensor

3. One computer data acquisition card

4. One computer (brand)

5. One color laser inkjet printer

6. A set of computer control software

7. Two 4Kg weights (one set for backup)

8. Four standard friction rings (two spare)

9. One copy of the product user manual

10. Product Qualification Certificate

11. Product packing list copy

12. Whole machine weight: approximately 87 kilograms

Hardware installation and wiring

1. Insert the power cord into the power socket at the back of the device.

2. Connect one end of the control and acquisition cable to the device control port and the other end to the computer.

3. Connect the computer wiring correctly

Sample requirements

The surface of the sample is flat, without defects such as bubbles, cracks, delamination, obvious impurities, and processing damage. Each group shall have no less than 3 samples.

Experimental conditions

In the experiment, the upper shaft remains stationary and the lower shaft rotates at 200 revolutions per minute. The friction pair performs sliding friction and grinds for 2 hours with a load of 20 kilograms. Depending on the material, other loads can be selected The experimental environment temperature is 23 ? 5 degrees Celsius

Test report

The test report should include the following contents:

A. Plastic name, specification, brand, and manufacturer;

B. The preparation method of the sample, the condition of the friction surface, and the number of samples measured;

C. Environmental temperature, temperature and state regulation conditions;

D. Circular ring material, hardness, smoothness, and outer diameter size;

E. Test load;

F. Test results: Measurement results of abrasion width or volume wear and friction coefficient;

G. Test date and personnel.

Experimental steps

1. The circular ring should be cleaned of oil stains and stored in a drying cylinder to prevent rusting.

2. After adjusting the state of the sample, weigh its mass (M1) using an analytical balance with a sensitivity of 0.1 milligrams.

3. Insert the sample into the fixture, calibrate the friction surface with an angle ruler, and ensure that its intersection with the circular ring is outside the center of the sample. Install the friction torque recording paper and start the machine to calibrate the zero point.

4. Carefully remove the oil stains on the sample and the ring using solvents such as ethanol and acetone that do not work with plastic. After that, do not touch the surface of the sample and ring with your hands.

5. Smoothly load to the selected load value.

6. After grinding for 2 hours, stop the machine to unload the load, remove the sample and ring, clean the surface of the sample, measure the width of the grinding mark with a measuring tool with an accuracy of not less than 0.02 millimeters, or weigh the sample mass (m2) after storing it in the test environment for 1 hour.

7. Read the torque value of friction force.

State adjustment

The state adjustment shall be carried out in accordance with GB2918-82 "Standard Environment for State Adjustment and Testing of Plastic Specimens", with a temperature of 23 ? 5 degrees Celsius and a temperature of 50 ? 10%.

我廠主要產(chǎn)品有:拉力材料試驗(yàn)機(jī),海綿泡沫落球回彈試驗(yàn)機(jī),海綿泡沫壓陷硬度測(cè)驗(yàn)儀,海綿泡沫疲勞壓陷試驗(yàn)機(jī),熔融指數(shù)儀,塑料滑動(dòng)摩擦磨損試驗(yàn)機(jī),電壓擊穿試驗(yàn)儀,塑料球壓痕硬度計(jì),馬丁耐熱試驗(yàn)儀,海綿泡沫拉伸強(qiáng)度試驗(yàn)機(jī),介電常數(shù)與介質(zhì)損耗測(cè)試儀,電容率測(cè)試儀,體積表面積電阻率測(cè)試儀,低溫脆性沖擊試驗(yàn)儀,維卡熱變形試驗(yàn)儀,啞鈴制樣機(jī),阿克隆磨耗試驗(yàn)機(jī),簡(jiǎn)支梁沖擊試驗(yàn)機(jī),懸臂梁沖擊試驗(yàn)機(jī),熔體流動(dòng)速率儀,無轉(zhuǎn)子硫化儀等。

想了解其它相關(guān)信息,歡迎登錄北京北廣精儀儀器設(shè)備有限公司網(wǎng)站或電詢我們相關(guān)人員。

關(guān)于儀器質(zhì)保:1、北廣儀器保證提供的設(shè)備為需方指定的全新設(shè)備,其各項(xiàng)技術(shù)指標(biāo)均符合相關(guān)的產(chǎn)品技術(shù)要求。2、設(shè)備經(jīng)客戶驗(yàn)收合格后,開始計(jì)算保修期,設(shè)備免費(fèi)保修期為壹年,設(shè)備在質(zhì)量保質(zhì)期內(nèi),產(chǎn)品在非人為損壞的情況下,由北廣儀器負(fù)責(zé)全保。北廣儀器的客服在得到通知后24小時(shí)內(nèi)響應(yīng),安排約定維修細(xì)節(jié)。3、質(zhì)保期后,我們免費(fèi)為您維修維護(hù)設(shè)備,除大型設(shè)備外所有設(shè)備一律返廠維修,經(jīng)檢驗(yàn)后,電話告知客戶問題所在及解決方式,經(jīng)客戶同意后進(jìn)行維修,維修后發(fā)回客戶,對(duì)于損壞及更換的零部件我們只收取成本費(fèi);如客戶不認(rèn)同我們的檢驗(yàn)結(jié)果,雙方另協(xié)商維修細(xì)節(jié)。

業(yè)務(wù)咨詢:932174181 媒體合作:2279387437 24小時(shí)服務(wù)熱線:15136468001 盤古機(jī)械網(wǎng) - 全面、科學(xué)的機(jī)械行業(yè)免費(fèi)發(fā)布信息網(wǎng)站 Copyright 2017 PGJXO.COM 豫ICP備12019803號(hào)