硫化橡膠體積表面電阻率測量儀 試樣處置

電極之間或測量電極與大地之間的雜散電流對于測試儀器的讀數沒有明顯的影響這一點很重要。測試時加電極到試樣上和安放試樣時均要極為小心,以免可能產生對測試結果有不良影響的雜散電流通道。

測量表面電阻時,不要清洗表面,除非另有協議或規定。除了同二材料的另一個試樣的未被觸模過的表面可觸及被測試樣外,表面被測部分不應被任何東西觸及。

硫化橡膠體積表面電阻率測量儀 技術指標

1、電阻測量范圍:1?104Ω~1?1018Ω。

2、電流測量范圍為:2?10-4A~1?10-16A

3、雙表頭顯示:3.1/2位LED顯示

4、內置測試電壓:10V、50V、100V、250、500、1000V

5、基本準確度:1% (*注)

6、使用環境: 溫度:0℃~40℃,相對濕度<80%

7、機內測試電壓:10/50/100/250/500/1000V任意切換

8、供電形式:AC 220V,50HZ,功耗約5W

9、儀器尺寸:285mm? 245mm? 120 mm

10、質量: 約2.5KG

防止漏電流的影響:對于高電阻材料,只有采取保護技術才能去除漏電流對測量的影響。保護技術就是在引起測量誤差的漏電路徑上安置保護導體,截住可能引起測量誤差的雜散電流,使之不流經測量回路或儀表。保護導體連接在一起構成保護端,通常保護端接地。測量體積電阻時,三電極系統的保護極就是保護導體。此時要求保護電極和測量電極間的試樣表面電阻高于與它并聯元件的電阻10~100倍。線路接好后,應首先檢查是否存在漏電。此時斷開與試樣連接的高壓線,加上電壓。如在測量靈敏度范圍內,測量儀器指示的電阻值為無限大,則線路無漏電,可進行測量。

溫度和濕度:固體絕緣材料的絕緣電阻率隨溫度和濕度的升高而降低,特別是體積電阻率隨溫度改變而變化非常大。因此,電瓷材料不但要測定常溫下的體積電阻率,而且還要測定高溫下的體積電阻率,以評定其絕緣性能的好壞。由于水的電導大,隨著濕度增大,表面電阻率和有開口孔隙的電瓷材料的體積電阻率急劇下降。因此,測定時應嚴格地按照規定的試樣處理要求和測試的環境條件下進行。

典型應用

1.測量防靜電鞋、導電鞋的電阻值

2、測量防靜電材料的電阻及電阻率

3、測量計算機房用活動地板的系統電阻值

4、測量絕緣材料電阻(率)

5、光電二極管暗電流測量

6、物理,光學和材料研究

電阻率的計算公式為:

ρL

R= —

S

ρ為電阻率——常用單位Ω?mm2/m

S為橫截面積——常用單位㎡

R為電阻值——常用單位Ω

L為導線的長度——常用單位m

電阻定律

導體的電阻R跟它的長度L、電阻率ρ成正比,跟它的橫截面積S成反比,這個規律就叫電阻定律(law of resistance),公式為R=ρL/S。其中ρ:制成電阻的材料的電阻率,L:繞制成電阻的導線長度,S:繞制成電阻的導線橫截面積,R:電阻值。

公式:R=ρL/S,R=U/I

ρ——制成電阻的材料電阻率,國際單位制為歐姆?米(Ω ? m);

L——繞制成電阻的導線長度,國際單位制為米(m);

S——繞制成電阻的導線橫截面積,國際單位制為平方米(m2) ;

R——電阻值,國際單位制為歐姆,簡稱歐(Ω);

U——電壓值,國際單位制為伏特,簡稱伏(v);

I——電流值,國際單位制為安培,簡稱安(A)。

其中:

ρ叫電阻率:某種材料制成的長1米、橫截面積是1平方毫米的導線的電阻,叫做這種材料的電阻率。是描述材料性質的物理量。國際單位制中,電阻率的單位是歐姆?米,常用單位是歐姆?平方毫米/米。與導體長度L,橫截面積S無關,只與物體的材料和溫度有關,有些材料的電阻率隨著溫度的升高而增大,有些反之。

電源

要求有很穩定的直流電壓源。這可用蓄電油或一個整流穩壓的電摞來提供。對電源的穩定度要求是由電壓變化導致的電流變化與被測電流相比可忽略不計。

加到整個試樣上的試驗電壓通常規定為100V、250V、500V、1000 V、2500 V、5000 V, 10000 V和15000 V。 常用的電壓是100V、500V和1000 V。

在某些情況下,試樣的電阻與施加電壓的極性有關

如果電阻是與極性有關的,則宜加以注明。取兩次電阻值的幾何平均值(對數算術平均值的反對數)作為結果。

由于試樣電阻可能與電壓有依存關系,因此應在報告中注明試驗電壓值。

power supply

Require a very stable DC voltage source. This can be provided by storing oil or a rectifier stabilized stack of electricity. The stability requirement for the power supply is that the current variation caused by voltage changes can be ignored compared to the measured current.

The test voltages applied to the entire sample are usually specified as 100V, 250V, 500V, 1000V, 2500V, 5000V, 10000V, and 15000V. The commonly used voltages are 100V, 500V, and 1000V.

In some cases, the resistance of the sample is related to the polarity of the applied voltage

If the resistance is polarity dependent, it should be noted. Take the geometric mean of two resistance values (the inverse of the logarithmic arithmetic mean) as the result.

Due to the possible dependence of sample resistance on voltage, the test voltage value should be indicated in the report.

試樣

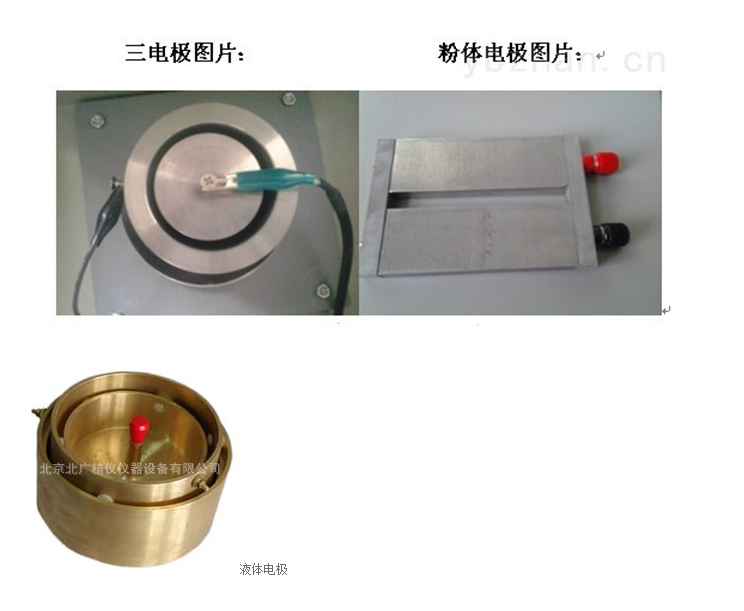

7.1體積電阻率

為測定體積電阻率,試樣的形狀不限,只要能允許使用第三電極來抵消表面效應引起的誤差即可。對于表面泄漏可忽略不計的試樣,測量體積電阻時可去掉保護,只要己證明去掉保護對結果的影響可忽略不計。

在被保護電極與保護電極之間的試樣表面上的間隙要有均勻的寬度,并且在表面泄漏不致于引起測量誤差的條件下間隙應盡可能的窄。lmm的間隙通常為切實可行的 小間隙。

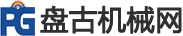

圖2及圖3給出了三電極裝置的例子。在測量體積電阻時,電極1是被保護電極,電極2為保護電 極,電極3為不保護電極。被保護電極的直徑d1(圖2)或長度l1(圖3)應至少為試樣厚度h的10倍,通 常至少為25mm。不保護電極的直徑d4(或長度[4)和保護電極的外直徑d3(或保護電極兩外邊緣之間 的長度[3)應該等于保護電極的內徑d2(或保護電極兩內邊緣之間的長度lz)加上至少2倍的試樣厚度。

7.2表面電阻率

為測定表面電阻率,試樣的形狀不限,只要允許使用第三電極來抵消體積效應引起的誤差即可。推薦使用圖2及圖3所示的三電極裝置。用電極1作為被保護電極,電極3作為保護電極,電極2作為不 保護電極。可直接測量電極1和2之間表面間隙的電阻。這樣測得的電阻包括了電極1和2之間的表面電阻和這兩個電極間的體積電阻。然而,對于很寬范圍的環境條件和材料性能,當電極尺寸合適時, 體積電阻的影響可忽略不計。為此,對于圖2和圖3所示的裝置,電極的間隙寬度g至少應為試樣厚度 的2倍,一般說來,1mm為切實可行的 小間隙。被保護電極尺寸d1(或長度l1)應至少為試樣厚度h的10倍,通常至少為25mm。

也可以使用條形電極或具有合適尺寸的其他裝置。

注:由于通過試樣內層的電流的影響,表面電阻率的計算值與試樣和電極的尺寸有很大的關系,因此,為了測定時可進行比較,推薦使用與圖2所示的電極裝置的尺寸相一致的試樣,其中d1= 50 mm, d2 = 60 mm, ds = 80 mm

sample

7.1 Volume resistivity

To determine the volume resistivity, the shape of the sample is not limited, as long as it allows the use of a third electrode to offset the errors caused by surface effects. For samples with negligible surface leakage, the protection can be removed when measuring the volume resistance, as long as it has been proven that removing the protection has negligible effects on the results.

The gap on the surface of the sample between the protected electrode and the protective electrode should have a uniform width, and the gap should be as narrow as possible under the condition that surface leakage does not cause measurement errors. The clearance of LMM is usually a feasible small clearance.

Examples of three electrode devices are shown in Figures 2 and 3. When measuring volume resistance, electrode 1 is the protected electrode, electrode 2 is the protected electrode, and electrode 3 is the unprotected electrode. The diameter d1 (Figure 2) or length l1 (Figure 3) of the protected electrode should be at least 10 times the thickness h of the specimen, typically at least 25mm. The diameter d4 (or length [4]) of the unprotected electrode and the outer diameter d3 (or length [3] between the two outer edges of the protected electrode) should be equal to the inner diameter d2 (or length lz between the two inner edges of the protected electrode) of the protected electrode plus at least twice the thickness of the sample.

7.2 Surface resistivity

To determine surface resistivity, the shape of the sample is not limited, as long as it allows the use of a third electrode to offset errors caused by volume effects. Recommend using the three electrode device shown in Figures 2 and 3. Use electrode 1 as the protected electrode, electrode 3 as the protective electrode, and electrode 2 as the unprotected electrode. The resistance of the surface gap between electrodes 1 and 2 can be directly measured. The resistance measured in this way includes the surface resistance between electrodes 1 and 2 and the volume resistance between these two electrodes. However, for a wide range of environmental conditions and material properties, the influence of volume resistance can be ignored when the electrode size is appropriate. Therefore, for the devices shown in Figures 2 and 3, the gap width g of the electrodes should be at least twice the thickness of the sample. Generally speaking, 1mm is a feasible small gap. The size d1 (or length l1) of the protected electrode should be at least 10 times the thickness h of the sample, usually at least 25mm.

Strip electrodes or other devices with appropriate dimensions can also be used.

Note: Due to the influence of the current passing through the inner layer of the sample, the calculated value of surface resistivity is closely related to the size of the sample and electrode. Therefore, for comparison during measurement, it is recommended to use a sample with the same size as the electrode device shown in Figure 2, where d1=50 mm, d2 = 60 mm, ds = 80 mm

工作原理

根據歐姆定律,被測電阻Rx等于施加電壓V除以通過的電流I。傳統的高阻計的工作原理是測量電壓V固定,通過測量流過取樣電阻的電流I來得到電阻值。從歐姆定律可以看出,由于電流I是與電阻成反比,而不是成正比,所以電阻的顯示值是非線性的,即電阻無窮大時,電流為零,即表頭的零位處是∞,其附近的刻度非常密,分辨率很低。整個刻度是非線性的。又由于測量不同的電阻時,其電壓V也會有些變化,所以普通的高阻計是精度差、分辨率低。

本儀器是同時測出電阻兩端的電壓V和流過電阻的電流I,通過內部的大規模集成電路完成電壓除以電流的計算,然后把所得到的結果經過A/D轉換后以數字顯示出電阻值,即便是電阻兩端的電壓V和流過電阻的電流I是同時變化,其顯示的電阻值不象普通高阻計那樣因被測電壓V的變化或電流I的變化而變,所以,即使測量電壓、被測量電阻、電源電壓等發生變化對其結果影響不大,其測量精度很高,從理論上講其誤差可以做到零,而實際誤差可以做到千分之幾或萬分之幾。

影響體積電阻率和表面電阻率測試的主要因素是溫度和濕度、電場強度、充電時間及殘余電荷等。體積電阻率可作為選擇絕緣材料的一個參數,電阻率隨溫度和濕度的變化而顯著變化。體積電阻率的測量常常用來檢查絕緣材料是否均勻,或者用來檢測那些能影響材料質量而又不能用其他方法檢測到的導電雜質。

絕緣材料用于電氣系統的各部件相互絕緣和對地絕緣,固體絕緣材料還起機械支撐作用。一般希望材料有盡可能高的絕緣電阻,并具有合適的機械、化學和耐熱性能。

Working principle

According to Ohm's Law, the measured resistance Rx is equal to the applied voltage V divided by the current I passing through. The working principle of traditional high resistance meters is to measure a fixed voltage V and obtain the resistance value by measuring the current I flowing through the sampling resistor. From Ohm's Law, it can be seen that since the current I is inversely proportional to the resistance, rather than directly proportional, the displayed value of the resistance is nonlinear. That is, when the resistance is infinite, the current is zero, and the zero position of the meter head is ∞. The scales near it are very dense, and the resolution is very low. The entire scale is non-linear. Moreover, due to the variation in voltage V when measuring different resistances, ordinary high resistance meters have poor accuracy and low resolution.

This instrument simultaneously measures the voltage V across the resistor and the current I flowing through the resistor. The voltage divided by the current is calculated through an internal large-scale integrated circuit, and the obtained result is then converted into a digital display of the resistance value through A/D conversion. Even if the voltage V across the resistor and the current I flowing through the resistor change simultaneously, the displayed resistance value does not change due to changes in the measured voltage V or current I like a regular high resistance meter. Therefore, even if changes in the measured voltage, measured resistance, power supply voltage, etc. do not have a significant impact on its results, its measurement accuracy is very high. Theoretically, its error can be zero, while the actual error can reach a few thousandths or tens of thousands.

The main factors affecting the testing of volume resistivity and surface resistivity are temperature and humidity, electric field strength, charging time, and residual charge. Volume resistivity can be used as a parameter for selecting insulation materials, and resistivity varies significantly with temperature and humidity. The measurement of volume resistivity is often used to check the uniformity of insulation materials or to detect conductive impurities that can affect material quality but cannot be detected by other methods.

Insulation materials are used for mutual insulation and ground insulation of various components in electrical systems, and solid insulation materials also serve as mechanical support. Generally, it is desirable for materials to have the highest possible insulation resistance and appropriate mechanical, chemical, and heat resistance properties.

條件處理

試樣的處理條件取決于被試材料,這些條件應在材料規范中規定。

推薦按GB/T 10580一2003進行條件處理;由各種鹽溶液所產生的相對溫度在IEC 60260中給出。

可以采用機械蒸發系統。

體積電阻率和表面電阻率都對溫度變化特別敏感。這種變化是指數式的。因此必須在規定的條件下來測量試樣的體積電阻和表面電阻。由于水分被吸收到電介質內是相對緩慢的過程,因此測定溫度對體積電阻率的影響需要延長處理期。吸收水分后通常會降低體積電阻。有些試樣可能需要處理數月才能達到平衡。

體積電阻率與表面電阻的區別

體積電阻率和表面電阻是材料電學性能的兩個重要參數,但兩者針對的測試對象和應用場景不同。以下是兩者的主要區別:

1. 定義與物理意義

體積電阻率(Volume Resistivity)

體積電阻率是衡量材料內部導電性能的參數,表示單位體積材料對電流的阻礙能力。

體積電阻率反映材料本身的絕緣或導電特性,與材料的成分、結構及溫度密切相關。例如,絕緣塑料的 可達12次方-16次方,而金屬的 僅為 10的-6}- 10^-4次方 。

表面電阻(Surface Resistance)

表面電阻是衡量材料表面導電性能的參數,表示電流沿材料表面流動時的阻礙能力。

表面電阻受材料表面狀態(如污染、濕度、氧化層)影響顯著,常用于評估材料的防靜電性能或漏電風險。

2. 測量方法與電極配置

-體積電阻率測量

- 電極設計:使用三電極系統(如保護環電極),確保電流僅通過材料內部,避免表面電流干擾。

- 測試標準:如 ASTM D257、IEC 60093。

- 適用場景:塊狀固體材料(如塑料、陶瓷、橡膠)的絕緣性能評估。

- 表面電阻測量

-電極設計:采用平行電極或同心環電極,使電流沿材料表面流動。

-測試標準:如 ASTM D4496、IEC 61340。

-適用場景:薄膜、涂層、紡織品等表面導電性能測試,或防靜電材料的篩選。

3. 應用領域差異

參數

體積電阻率:

核心用途評估材料內部絕緣

典型應用電線絕緣層、電子封裝材料、高壓設備

關鍵影響因素材料成分、溫度、雜質濃度

表面電阻:評估材料表面導電/防靜電性能 導電性

影響因素表面清潔度、濕度、污染、氧化層

4. 實例對比

絕緣塑料板:

體積電阻率高于15次方,說明內部絕緣性能優異;

- 表面電阻可能因吸附水分而降低于12次方,表明表面存在微弱導電性。

5. 總結

體積電阻率:表征材料整體的絕緣或導電能力,是材料本征屬性的體現。

表面電阻:反映材料表面的導電特性,易受環境因素和表面狀態影響。

兩者在科研、工業質檢中常需同時測試,以全面評估材料的電學性能(如高壓絕緣材料需高體積電阻率 高表面電阻,而防靜電材料需中等體積電阻率 低表面電阻)。

業務咨詢:932174181 媒體合作:2279387437 24小時服務熱線:15136468001 盤古機械網 - 全面、科學的機械行業免費發布信息網站 Copyright 2017 PGJXO.COM 豫ICP備12019803號