直流表面電阻率測試儀 表面電阻率surface resistivity

在絕緣材料的表面層里的直流電場強度與線電流密度之商,即單位面積內的表面電阻。面積的大

小是不重要的。

注:表 面 電 阻 率 的S1單 位 是Q。實 際 上 有 時 也 用“歐 每 平 方 單 位”來 表 示 。

直流表面電阻率測試儀 測試

測量時從低檔位逐漸拔往高檔,每撥一次稍停留1~2秒以使觀察顯示數字, 當被測電阻大于儀器測量量程時,電阻表顯示“1”,此時應繼續將儀器撥到量程更高的位置,當測量儀器有顯示值時應停下,當前的數字乘以檔次即是被測電阻值。當有顯示數字時不要再往更高次檔撥,否測儀器會過量程,機內保護電路開始工作,儀器測量準確度會下降。

標準配置:

1、測試儀器 1臺

2、.電源線 1條

3、測試電極 1套

4、使用說明書 1份

5、測試主機 1臺

6、出廠測試報告 1份

7、上位機連接線 1條

8、屏蔽箱 1個

9、測試夾 1套

10、232數據串口組件1套

應用

電阻率較低的物質被稱為導體,常見導體主要為金屬,而自然界中導電性佳的是銀,其次為半導體,硅鍺。當存在外電場時,金屬的自由電子在運動中不斷和晶格節點上做熱振子的正離子相碰撞,使電子運動受到阻礙,因而就具有了一定的電阻。其他不易導電的物質如玻璃、橡膠等,電阻率較高,一般稱為絕緣體。介于導體和絕緣體之間的物質(如硅)則稱半導體。電阻率的科學符號為 ρ(Rho)。 已知物體的電阻,可由電阻率ρ、長度l與截面面積A計算:ρ=RA/I,在該式中, 電阻R單位為歐姆,長度l單位為米,截面面積A單位為平方米,電阻率 ρ單位為歐姆?米

工作原理

根據歐姆定律,被測電阻Rx等于施加電壓V除以通過的電流I。傳統的高阻計的工作原理是測量電壓V固定,通過測量流過取樣電阻的電流I來得到電阻值。從歐姆定律可以看出,由于電流I是與電阻成反比,而不是成正比,所以電阻的顯示值是非線性的,即電阻無窮大時,電流為零,即表頭的零位處是∞,其附近的刻度非常密,分辨率很低。整個刻度是非線性的。又由于測量不同的電阻時,其電壓V也會有些變化,所以普通的高阻計是精度差、分辨率低。

本儀器是同時測出電阻兩端的電壓V和流過電阻的電流I,通過內部的大規模集成電路完成電壓除以電流的計算,然后把所得到的結果經過A/D轉換后以數字顯示出電阻值,即便是電阻兩端的電壓V和流過電阻的電流I是同時變化,其顯示的電阻值不象普通高阻計那樣因被測電壓V的變化或電流I的變化而變,所以,即使測量電壓、被測量電阻、電源電壓等發生變化對其結果影響不大,其測量精度很高,從理論上講其誤差可以做到零,而實際誤差可以做到千分之幾或萬分之幾。

電阻的作用:

電阻在電路中的作用:利用著名的歐姆定律可以利用電阻控制電路中的電壓、電流。

電阻的主要物理特征就是可以變電能為熱能,因此熱水器中的發熱元件、電燈泡、電燙斗就是利用了電阻的作用制成的。另外電阻有怕熱的特性,當導體材料溫度升高時材料的電阻率會增大(有些材料則表現為減小),因此利用電阻的這種特性可以制作溫度測量計(不知道你看見過沒,插一根“鐵絲”就能測量溫度的方法就是利用了這種電阻材料作用的)。

另外一些材料的電阻還會受到光線照射的印象,而利用這樣的材料可以制成光敏電阻,利用這點作用可以方便的設計光控電路以及光的測量和光電轉換等領域。

技術指標

1、電阻測量范圍:1?104Ω~1?1018Ω。

2、電流測量范圍為:2?10-4A~1?10-16A

3、雙表頭顯示:3.1/2位LED顯示

4、內置測試電壓:10V、50V、100V、250、500、1000V

5、基本準確度:1% (*注)

6、使用環境: 溫度:0℃~40℃,相對濕度<80%

7、機內測試電壓:10/50/100/250/500/1000V任意切換

8、供電形式:AC 220V,50HZ,功耗約5W

9、儀器尺寸:285mm? 245mm? 120 mm

10、質量: 約2.5KG

范圍:

1本試驗方法包含直流絕緣電阻,體積電阻和表面電阻的測量所用直流程序。通過該測量及樣本和電極的幾何尺寸,可以計算出電絕緣材料的體積電阻和表面電阻,同時還可以計算出相應的電導和電導率。

2這些試驗方法不適用于測量中等導電材料的電阻/電導。這些材料評估可采用試驗方法D4496。

3本標準描述了幾種可選擇的測量電阻(或電導)的普通備用方法。特殊材料科采用合適的標準ASTM試驗方法進行測試,這些特殊材料具有電壓應力范圍和有限起電時間,同時規定了樣本結構和電極幾何形狀。這些個別特殊試驗方法將能更好得定義測量值的精度和偏差。

4本標準并沒有完全列舉所有的安全聲明,如果有必要,根據實際使用情況進行斟酌。使用本規范前,使用者有責任制定符合安全和健康要求的條例和規范,并明確該規范的使用范圍。

主要應用范圍

材料高阻測試測量如防靜電產品(防靜電鞋、防靜電塑料橡膠制品、計算機房防靜電活動地板等)電阻值的檢測;

材料體電阻(率)和表面電阻(率)測量;

電化學和材料測試,以及物理,光學和材料研究;

微弱電流測量如光電效應和器件暗電流測量。

電阻的作用:

電阻在電路中的作用:利用著名的歐姆定律可以利用電阻控制電路中的電壓、電流。

電阻的主要物理特征就是可以變電能為熱能,因此熱水器中的發熱元件、電燈泡、電燙斗就是利用了電阻的作用制成的。另外電阻有怕熱的特性,當導體材料溫度升高時材料的電阻率會增大(有些材料則表現為減小),因此利用電阻的這種特性可以制作溫度測量計(不知道你看見過沒,插一根“鐵絲”就能測量溫度的方法就是利用了這種電阻材料作用的)。

另外一些材料的電阻還會受到光線照射的印象,而利用這樣的材料可以制成光敏電阻,利用這點作用可以方便的設計光控電路以及光的測量和光電轉換等領域。

測試步驟:

1、測試溫度23?2℃,相對濕度65?5%,無外界電磁場干擾環境中進行。

2、測試時對試樣所加電壓為100V~500V的直流電壓,選擇電壓檔次。

3、將試樣倒入高壓電極內,使液面剛好和環電極下緣全部接觸為止。

4、將充分放電后的試樣和電極,按固體(液體)體積及表面電阻率測試儀要求接線。

外電極(高壓電極)接高固體(液體)體積及表面電阻率測試儀的高壓輸出端。

內電極(測量電極)接固體(液體)體積及表面電阻率測試儀的測量端。

中電極(環電極)接固體(液體)體積及表面電阻率測試儀的接地端。

5、儀器預熱30分鐘,穩定后調整儀器(調零),加上試驗1分鐘,讀取電阻指示值,然后放電1分鐘,再測試一次,以二次的算術平均值作為試驗樣品電阻指示值。

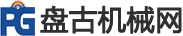

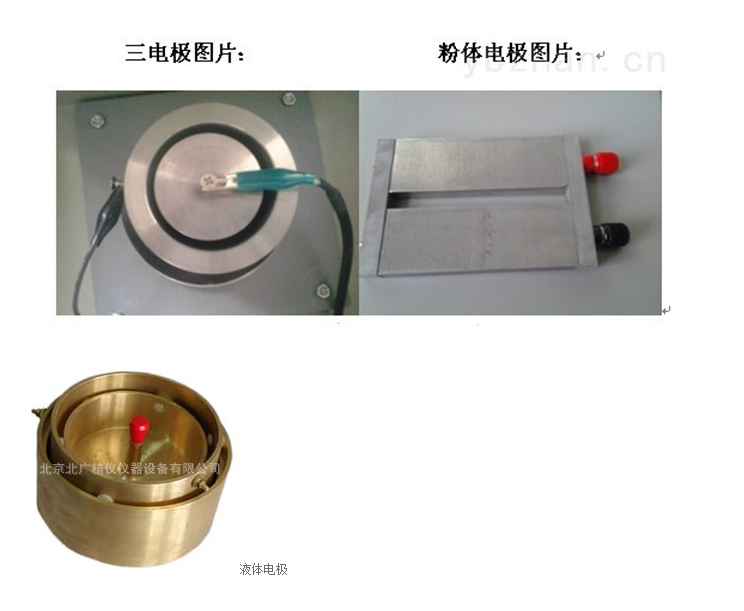

電極electrodes

電極是具有一定形狀、尺寸和結構的與被測試樣相接觸的導體。

注:絕緣電阻是加在與試樣相接觸的兩電極之間的直流電壓與通過兩電極的總電流之商 絕緣電阻取決于試樣的表面電阻和體積電阻(見GB/T 10064-2006)

符合標準:

GB/T 1410-2006《 固體絕緣材料體積電阻率和表面電阻率試驗方法》

ASTM D257-99《絕緣材料的直流電阻或電導試驗方法》

GB/T 10581-2006《絕緣材料在高溫下電阻和電阻率的試驗方法》

GB/T 1692-2008《硫化橡膠 絕緣電阻率的測定》

GB/T 2439-2001《硫化橡膠或熱塑性橡膠 導電性能和耗散性能電阻率的測定》

GB/T 12703.4-2010《紡織品 靜電性能的評定 第4部分:電阻率》

GB/T 10064-2006_《測定固體絕緣材料絕緣電阻的試驗方法》

重要性和用途:

1絕緣材料用于電子系統彼此和與地面之間隔離,該材料能提供零部件的機械支撐。由于此用途,通常要求具有盡可能高的絕緣電阻,以與可接受的機械、化學和耐熱性能一致。因為絕緣電阻或電導組合了體積和表面電阻或電導,當實際使用時,要求試驗樣本和電極具有相同的形式,此時的測量值是非常有用的。表面電阻或電導隨著濕度發生快速變化,然而體積電阻或電導則稍微變化,盡管總的變化在一些變化可能更大。

2電阻或電導可用于間接預測某些材料的低頻率電介質擊穿和損耗因數性能。電阻或電導通常作為濕度含量,固化程度,機械連續性或不同類型老化的間接測量方式。這些間接測量的效用取決于通過理論或經驗研究確立的相關度。表面電阻的降低可導致因為電場強度降低而發生電介質擊穿電壓的增加,或者由于應力面積的增加而發生電介質擊穿電壓的降低。

3所有的電介質電阻或電導都取決于電化時間長短和施加的電壓值(除了普通的環境變量之外)。這些因素必須已知,同時報告,以使得電阻或電導測量值有意義。在電絕緣材料工業中,形容詞“表觀”通常適用于在任意選擇電化時間條件下獲得的電阻值。見X1.4。

4體積電阻或電導可通過在特定應用場合設計某個絕緣體使用的電阻和尺寸數據計算得出。研究已經表明電阻或電導隨著溫度和濕度的變化而變化(1,2,3,4)4,同時在設計工作條件時,必須已知這種變化。體積電阻或電導測量值通常用于檢查絕緣材料的均勻性,或者對于加工,可探測影響材料質量的導電雜質,而這不容易通過其它方法觀察到。

5體積電阻超過1021Ω?cm(1019Ω?cm)時,樣本在普通實驗室條件測試獲得的數值計算得出體積電阻,如果結果確實可疑,則應考慮通常使用的測量設備的局限性。

6表面電阻或電導不能精確測量,只能近似測量,因為體積電阻或電導總是受到測量方法的影響。測量值還受到表面污染的影響。表面污染及其積聚速度受到許多因素的影響,包括靜電充電和界面張力。這些因素反過來可以影響表面電阻。當包括污染,但是在通常常識下判斷不是電絕緣材料的材料性能時,此時表面電阻或電導可視為與材料性能相關。

Compliant with standards:

GB/T 1410-2006 "Test Method for Volume and Surface resistivity of Solid Insulation Materials"

ASTM D257-99 "Test Method for DC Resistance or Conductivity of Insulation Materials"

GB/T 10581-2006 "Test method for resistance and resistivity of insulating materials at high temperatures"

GB/T 1692-2008 "Determination of Insulation Resistance of Vulcanized Rubber"

GB/T 2439-2001 "Determination of Electrical Conductivity and Dissipation Properties of Vulcanized Rubber or Thermoplastic Rubber"

GB/T 12703.4-2010 "Evaluation of electrostatic properties of textiles - Part 4: Electrical resistivity"

GB/T 10064-2006_ "Test Method for Determining Insulation Resistance of Solid Insulation Materials"

Importance and purpose:

1. Insulation material is used to isolate electronic systems from each other and from the ground, providing mechanical support for components. Due to this purpose, it is usually required to have the highest possible insulation resistance to be consistent with acceptable mechanical, chemical, and heat resistance performance. Because insulation resistance or conductivity combines volume and surface resistance or conductivity, when in actual use, it is required that the test sample and electrode have the same form, and the measured values at this time are very useful. Surface resistance or conductivity changes rapidly with humidity, while volume resistance or conductivity changes slightly, although the overall change may be greater in some cases.

Resistance or conductivity can be used to indirectly predict the low-frequency dielectric breakdown and loss factor performance of certain materials. Resistance or conductivity is usually used as an indirect measurement method for humidity content, curing degree, mechanical continuity, or different types of aging. The utility of these indirect measurements depends on the correlation established through theoretical or empirical research. The decrease in surface resistance can lead to an increase in dielectric breakdown voltage due to a decrease in electric field strength, or a decrease in dielectric breakdown voltage due to an increase in stress area.

All dielectric resistances or conductivities depend on the duration of electrification and the applied voltage value (except for common environmental variables). These factors must be known and reported simultaneously to make the resistance or conductivity measurements meaningful. In the electrical insulation material industry, the adjective "apparent" is usually applied to the resistance value obtained under any chosen electrochemical time conditions. See X1.4.

The volume resistance or conductivity can be calculated by designing the resistance and size data of an insulator for specific applications. Research has shown that resistance or conductivity varies with temperature and humidity (1,2,3,4), and this variation must be known when designing operating conditions. Volume resistance or conductivity measurements are commonly used to check the uniformity of insulation materials, or for processing, to detect conductive impurities that affect material quality, which are not easily observed through other methods.

When the volume resistance exceeds 1021 Ω? cm (1019 Ω? cm), the sample's volume resistance is calculated based on the values obtained from testing under normal laboratory conditions. If the results are indeed suspicious, the limitations of commonly used measuring equipment should be considered.

Surface resistance or conductivity cannot be accurately measured and can only be approximately measured, as volume resistance or conductivity is always affected by the measurement method. The measured values are also affected by surface contamination. Surface pollution and its accumulation rate are influenced by many factors, including electrostatic charging and interfacial tension. These factors can in turn affect surface resistance. When pollution is included, but it is common sense to judge that the material properties are not electrical insulation materials, surface resistance or conductivity can be considered related to the material properties.

Surface resistivity

The quotient of the direct current electric field strength and the line current density in the surface layer of insulating materials, which is the surface resistance per unit area. Large area

Small is not important.

Note: The unit of S1 for surface resistivity is Q. In fact, sometimes it is also expressed as' Euro per square unit '.

test

When measuring, gradually shift from low gear to high gear, pause for 1-2 seconds each time to observe the displayed number. When the measured resistance is greater than the measuring range of the instrument, the resistance meter displays "1". At this time, continue to move the instrument to a higher range position. When the measuring instrument displays a value, stop. The current number multiplied by the level is the measured resistance value. When there are displayed numbers, do not dial higher gears, otherwise the measuring instrument will exceed the range, the internal protection circuit will start working, and the measurement accuracy of the instrument will decrease.

Standard configuration:

1. 1 testing instrument

2. 1 power cord

3. Test electrode 1 set

4. 1 copy of user manual

5. Test host 1 unit

6. 1 copy of factory test report

7. 1 upper computer connection cable

8. 1 shielding box

9. Test clip 1 set

10. One set of 232 data serial port components

application

Substances with low electrical resistivity are called conductors, and common conductors are mainly metals. In nature, silver has good conductivity, followed by semiconductors such as silicon and germanium. When there is an external electric field, the free electrons of the metal constantly collide with the positive ions of the lattice nodes that act as thermal oscillators, hindering the movement of electrons and thus possessing a certain resistance. Other materials that are not easily conductive, such as glass, rubber, etc., have high electrical resistivity and are generally referred to as insulators. The substance between a conductor and an insulator, such as silicon, is called a semiconductor. The scientific symbol for resistivity is ρ (Rho). Given the resistance of an object, it can be calculated from the resistivity ρ, length l, and cross-sectional area A ρ=RA/I,In this equation, the unit of resistance R is ohms, the unit of length l is meters, the unit of cross-sectional area A is square meters, and the unit of resistivity ρ is ohm meters

Working principle

According to Ohm's Law, the measured resistance Rx is equal to the applied voltage V divided by the current I passing through. The working principle of traditional high resistance meters is to measure a fixed voltage V and obtain the resistance value by measuring the current I flowing through the sampling resistor. From Ohm's Law, it can be seen that since the current I is inversely proportional to the resistance, rather than directly proportional, the displayed value of the resistance is nonlinear. That is, when the resistance is infinite, the current is zero, and the zero position of the meter head is ∞. The scales near it are very dense, and the resolution is very low. The entire scale is non-linear. Moreover, due to the variation in voltage V when measuring different resistances, ordinary high resistance meters have poor accuracy and low resolution.

This instrument simultaneously measures the voltage V across the resistor and the current I flowing through the resistor. The voltage divided by the current is calculated through an internal large-scale integrated circuit, and the obtained result is then converted into a digital display of the resistance value through A/D conversion. Even if the voltage V across the resistor and the current I flowing through the resistor change simultaneously, the displayed resistance value does not change due to changes in the measured voltage V or current I like a regular high resistance meter. Therefore, even if changes in the measured voltage, measured resistance, power supply voltage, etc. do not have a significant impact on its results, its measurement accuracy is very high. Theoretically, its error can be zero, while the actual error can reach a few thousandths or tens of thousands.

The function of resistance:

The role of resistance in circuits: Using the famous Ohm's law, resistance can be used to control the voltage and current in a circuit.

The main physical characteristic of resistance is that it can convert electrical energy into thermal energy, so the heating elements, light bulbs, and electric irons in water heaters are made using the effect of resistance. In addition, resistors have the characteristic of being sensitive to heat. When the temperature of the conductor material increases, the resistivity of the material will increase (some materials show a decrease). Therefore, using this characteristic of resistors can be used to make temperature measuring instruments (I don't know if you have seen it, the method of measuring temperature by inserting a "wire" is based on the effect of this resistor material).

In addition, the resistance of some materials can also be affected by light exposure, and using such materials can make photoresistors. This can facilitate the design of light control circuits, as well as the measurement and photoelectric conversion of light.

TECHNICAL INDEX

1. Resistance measurement range: 1 ? 104 Ω~1 ? 1018 Ω.

2. The current measurement range is: 2?10-4A~1?10-16A

3. Dual header display: 3.1/2 LED display

4. Built in test voltage: 10V, 50V, 100V, 250, 500, 1000V

5. Basic accuracy: 1% (* note)

6. Usage environment: Temperature: 0 ℃~40 ℃, relative humidity<80%

7. Internal test voltage: 10/50/100/250/500/1000V can be switched freely

8. Power supply form: AC 220V,50HZ,Power consumption is about 5W

9. Instrument size: 285mm ? 245mm ? 120mm

10. Quality: Approximately 2.5KG

體積表面電阻率測試儀是一種用于測量材料絕緣性能的精密儀器,廣泛應用于多個行業,主要涉及對材料電絕緣性能有嚴格要求的領域。北京北廣精儀儀器設備有限公司聲場的體積表面電阻率測試儀主要用于以下主要適用行業及具體應用場景:

1. 電子與半導體行業

應用:測試PCB基板、絕緣薄膜、封裝材料、半導體晶圓等的電阻率,確保其絕緣性能滿足電子元件防短路、防漏電的要求。

案例:評估手機電路板在高濕度環境下的絕緣可靠性。

2. 電力與能源行業

應用:檢測電纜絕緣層、變壓器油、復合絕緣子等材料的電阻率,保障高壓設備的安全運行。

案例:高壓電纜出廠前的絕緣性能驗證。

3. 航空航天與汽車制造

應用:評估飛機復合材料、汽車線束、電池隔膜等材料的電絕緣性,防止靜電積聚或電磁干擾。

案例:新能源汽車電池組絕緣材料的質量控制。

4. 科研與新材料開發

應用:研究石墨烯、納米涂層等新型材料的導電/絕緣特性,優化材料配方。

案例:柔性顯示技術中透明導電薄膜的研發測試。

5. 醫療設備與生物材料

應用:檢測醫用塑料、導管、植入材料的絕緣性能,確保患者安全。

案例:心臟起搏器絕緣外殼的生物兼容性測試。

6. 塑料與橡膠工業

應用:質量控制環節中測量工程塑料、硅橡膠等材料的電阻率,用于防靜電包裝或絕緣部件生產。

案例:防靜電托盤用于芯片運輸前的電阻率達標測試。

6. 軍事與國防

應用:評估隱身涂層、雷達吸波材料等的電學性能。

7 案例:軍用無人機復合材料的電磁屏蔽效能測試。

8. 建材與家居行業

應用:檢測地板、墻板的防靜電性能(如數據中心地板)或絕緣性能(如電工套管)。

案例:潔凈室防靜電地板的驗收測試。

9.能源存儲(電池與電容器)

應用:測量隔膜、電解質的電阻率,優化鋰電池或超級電容器的性能。

案例:鋰電隔膜孔隙率對離子傳導性的影響研究。

10. 質量控制與認證機構

應用:作為第三方檢測工具,依據ISO/ASTM標準對材料進行認證(如UL認證、RoHS合規性)。

案例:出口電子產品的絕緣安全認證測試。

關鍵測試參數

體積電阻率(Ω?cm):反映材料內部的絕緣性能。

表面電阻率(Ω/sq):評估材料表面的導電/防靜電特性。

行業標準參考

測試常遵循國際標準如IEC 60093、ASTM D257、GB/T 1410等,確保數據可比性。

總之,該儀器是材料電學性能評估的核心設備,覆蓋從基礎研究到工業生產的全鏈條需求,尤其在需要高可靠性絕緣或可控導電性的場景中不可或缺。

業務咨詢:932174181 媒體合作:2279387437 24小時服務熱線:15136468001 盤古機械網 - 全面、科學的機械行業免費發布信息網站 Copyright 2017 PGJXO.COM 豫ICP備12019803號